Mississippi State University 2006

From 2006.igem.org

(Difference between revisions)

| Line 64: | Line 64: | ||

* We built the following two constructs:<br> | * We built the following two constructs:<br> | ||

| - | :[[Image: | + | :[[Image:untitled4.gif]] |

|} | |} | ||

Revision as of 20:48, 27 October 2006

The TeamFaculty Members:

Students:

|

Introduction

|

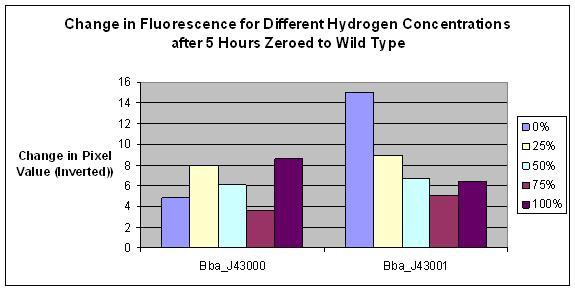

H2 Reporter

|

Results |

Discussion

|

Accomplishments

|